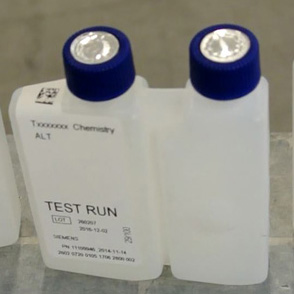

‘L-seal’ and ‘Watchstrap’ tamper labels are increasingly replacing shrink sleeves on jar products due to customer efforts to reduce plastics. Our highly innovative rotary adaption solution allows these labels to be applied and perfectly adapted at high speed, further complemented via the possibility of a non-stop, continual running, dual-head machine configuration, as shown here on a uniquely configured ALline…