ALTech have designed and built a base labelling system made for a market leader in the pet food industry. It has been placed within their production / packaging line, where the products travel upside down with the opening / labelling side facing the conveyor. The machine provides product spacing and transportation and is largely used to apply base labels at a typical running speed of 500 products per minute (30,000 per hour). It is also configured to apply top and bottom labelling for single pack items. To avoid production line stoppage, the line has been equipped with two mirrored and parallel solutions which are able to work either at the same time or alternatively.

The machine is based on an ALbelt solution equipped with a two section conveyor and side-belts to provide product spacing and stability during the labelling process. The high performance ALritma X labelling heads allow the system to label the constantly travelling products at over 50 meters per minute.

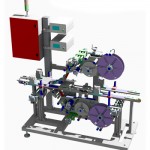

System overview (showing non-stop operation via line change over redundancy)

System running at over 500 products per minute