Thank you for contacting us, we will respond to your enquiry as soon as possible.

Required fields are missing. Please check that ALL fields marked with * are properly filled in.

You Enquiry is currently being sent.

There was an error sending your message. Please check to ensure ALL required fields are filled in and correct then try again. If this persists then please Contact the webmaster.

Required fields are missing. Please check that ALL fields marked with * are properly filled in.

Thank you for requesting a quotation from us. We endeavour to process quotation requests within 24 hours during normal working hours.

You Enquiry is currently being sent.

There was an error sending your message. Please check to ensure ALL required fields are filled in and correct then try again. If this persists then please Contact the webmaster.

There was an error logging in. Please check your username and password.

Success you are now logged in.

Please Wait

There was an error logging in. Please check your username and password.

ALstep is based on a robust, reliable mechanical structure which can be orientated in any rotation. It can be fitted into particularly restricted areas and thanks to side access web threading and a numbered web path, allows a fast, easy label change over.

ALstep comes in two size versions - S or M - for label widths up to 100mm and 200 mm respectively. Its maximum label dispensing speed is as high as 30m/min. (20m/min in the M version).This performance is made possible thanks to a powerful stepper motor and accurate label web tension control.

Designed in a modular manner, ALstep includes a comprehensive selection of application options to solve even the most complex label application requirements.

A few of our standard label application solutions include:

On the very rare occasion where a standard application solution does not exist, we have the experience and expertise to design custom label application solutions or machine configurations.

ALstep label applicators can hold label reels up to 300mm diameter (approx. 450m) on industry-standard 76mm core, for extended operation.

The unwind/rewind holding disks are manufactured from highly resilient anodised aluminium, making them virtually unbreakable. The separate LCD control box (also anodised aluminium) is 'fanless', allowing its operation in even the harshest industrial environments.

Deliberately simple in its interface, but with powerful control algorithms, ALstep's controller enables the operator to enter all labelling parameters electronically via an intuitive six-digit LCD display. This removes the need to manually move label or product sensors, as per lesser machines. It also includes a product sensor 'shift register', allowing positioning to ensure this device does not foul or clutter the application position.

Control functions include:

ALstep can be equipped with an array of ancillary devices to solve specific labelling problems, such as:

ALstep is also available in a special ultra-low-cost 'E' (Economical) form for label widths up to 100 mm leading edge, at a maximum application speed of 18m/min. This machine includes reduced dimensions unwind and rewind capacities (as well as the overall machine size) and is ideal for simple low-speed applications where cost reduction is crucial.

ALstep E features a smaller stepper motor and simplified fanless control box, allowing digital adjustment of the main labelling parameters (speed, pre-dispensing and label delay). However, it excludes the ability to encode the machine.

It can provide an alarm signal in case of web break and end-of-roll, but is not compatible with any further accessories of the standard ALstep.

ALstep Labelling Trays

ALstep Labelling Trays

ALstep Cylindrical Chubs Labelling

ALstep Cylindrical Chubs Labelling

ALstep Flat Box Labelling

ALstep Flat Box Labelling

ALstep Drums Labelling

ALstep Drums Labelling

ALstep Pneumatic Peeler Sacks

ALstep Pneumatic Peeler Sacks

ALstep M Case Labelling

ALstep M Case Labelling

Promo Labelling on Ready Meals

Promo Labelling on Ready Meals

ALstep with Tamp Applicator

ALstep with Tamp Applicator

ALstep with Flat Pouches

ALstep with Flat Pouches

ALstep M Hanging Pouch Filling Machine

ALstep M Hanging Pouch Filling Machine

ALstep Lid Labelling

ALstep Lid Labelling

Promo Labelling on Vacuum Skin Packs

Promo Labelling on Vacuum Skin Packs

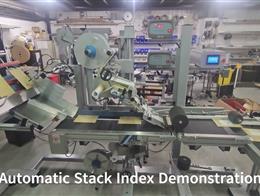

ALstep M Top & Bottom with Pick-Place Feeder

ALstep M Top & Bottom with Pick-Place Feeder

Contact ALTech UK to discuss your requirements with our experienced and knowledgeable team.

Contact UsContact ALTech UK to discuss your requirements with our experienced and knowledgeable team.

Contact UsContact ALTech UK to discuss your requirements with our experienced and knowledgeable team.

Contact Us