Thank you for contacting us, we will respond to your enquiry as soon as possible.

Required fields are missing. Please check that ALL fields marked with * are properly filled in.

You Enquiry is currently being sent.

There was an error sending your message. Please check to ensure ALL required fields are filled in and correct then try again. If this persists then please Contact the webmaster.

Required fields are missing. Please check that ALL fields marked with * are properly filled in.

Thank you for requesting a quotation from us. We endeavour to process quotation requests within 24 hours during normal working hours.

You Enquiry is currently being sent.

There was an error sending your message. Please check to ensure ALL required fields are filled in and correct then try again. If this persists then please Contact the webmaster.

There was an error logging in. Please check your username and password.

Success you are now logged in.

Please Wait

There was an error logging in. Please check your username and password.

ALline C is an extremely robust and modular high-performance wraparound labelling machine, designed for in-line use (or standalone operation, usually with rotary infeed and outfeed tables) with virtually any cylindrical round product.

It can be configured in an almost infinitely variable way, with a choice of spacing systems, labelling heads and coding options. These are chosen according to the products to be labelled, the environment the machine will be placed, and the performance requirements of the application.

Typical label application operation speeds vary between 60-200 products per minute, dependent on the label and product dimensions, with the potential in some applications, to exceed 250 products per minute where a scroll spacing unit is employed (to guarantee a perfect regularity of product pitch).

At the heart of any ALline C labelling system is our advanced ALritma labelling head. Control of this device, along with all the other various elements of the machine, is operated via a standard 'machine visualisation' touch screen control system, mounted in an ergonomic upper position.

This sophisticated control system, allows complete label/product recipe setups to be stored and recalled (rather than just the parameters of the labelling head, as is usual in most competitor machines, or our lesser wraparound machines), with optimal speeds for the conveyor/wraparound and product pitch spacing stored as part of this recipe, along with the various position values of the devices (via counters schedule). This means you can be assured of both the perfect product setup and also consistency in label position between batches, so the product looks the same on the shelf.

Standard product spacing solutions (gapping systems) for the ALline C include:

ALline C machines are most commonly based on a well-proven 'direct-wraparound' labelling concept, where the label is dispenced on the product just as it starts to rotate on the conveyor, then continuing to feed as the product moves forward rotated at roughly two times the speed of the main conveyor (to maintain its relative pitch spacing)

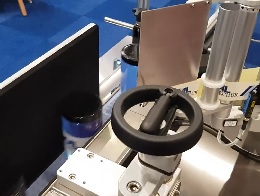

Two versions of direct wraparound module exist; both heavy-duty with extraction slide and height adjustment of the wraparound belt (via handwheel), but with a premium version also offering four further handwheel position adjustments to provide an ultra-high-precision and repeatable setup of the counter plate (as well as the drive belt).

Alternatively, in certain situations, we can also employ a particularly innovative 'vacuum belt' wraparound concept. Here the label is dispensed on to the vacuum belt and then joined to the product independently to the labelling head. This provides the advantage of being able to vary the firing position of the label (perhaps to register to a just applied neck or top label) as well as the possibility of applying more than one label per product; i.e. for high-speed front/back application.

The core wraparound application solutions for ALline C can be visualised here:

ALline C's robust, compact base structure, provides an ultra-rigid platform to ensure complete rigidity and positional continuity of its various elements - critical to consistent, repeatable, accurate labelling which is a core requirement of the machine.

They include as standard a stainless steel top plate, (extendable) chain conveyor and module components with an upper mounted control panel, providing a user-friendly operator interface and of course inherent liquids protection (as well as advanced remote connection capabilities).

Where required, ALline C can be specified with an enclosure and/or full stainless 304 or 316 construction - i.e. for wet or corrosive environments.

They can also be configured with label application checking devices and product rejection systems - or optimised for stand-alone solutions, with rotary in feed and outfeed tables (generally able to be driven from the main conveyor drive making them especially economic to include).

ALline C - Features Overview

ALline C - Features Overview

Vacuum Wraparound with Tamper Adaption

Vacuum Wraparound with Tamper Adaption

Beer Bottles Neck, Vacuum Front, Back

Beer Bottles Neck, Vacuum Front, Back

ALline C 500ml Cans (Offline RotaryTables)

ALline C 500ml Cans (Offline RotaryTables)

Pharma Vials with Tray Loading

Pharma Vials with Tray Loading

Non-Stop Twin Head Jars

Non-Stop Twin Head Jars

ALline C with Scroll (Highspeed Beer Cans)

ALline C with Scroll (Highspeed Beer Cans)

High-Speed Full Height Wraparound

High-Speed Full Height Wraparound

1 ltr Bottles Rotary Infeed & Outfeed

1 ltr Bottles Rotary Infeed & Outfeed

ALline C Built Below an Existing Line Conveyor

ALline C Built Below an Existing Line Conveyor

Rotary Infeed with Extended Outfeed

Rotary Infeed with Extended Outfeed

Front-Back Vacuum Jars (High Speed)

Front-Back Vacuum Jars (High Speed)

ALline C Transparent Body + Neck Label

ALline C Transparent Body + Neck Label

Contact ALTech UK to discuss your requirements with our experienced and knowledgeable team.

Contact UsContact ALTech UK to discuss your requirements with our experienced and knowledgeable team.

Contact UsContact ALTech UK to discuss your requirements with our experienced and knowledgeable team.

Contact Us