Thank you for contacting us, we will respond to your enquiry as soon as possible.

Required fields are missing. Please check that ALL fields marked with * are properly filled in.

You Enquiry is currently being sent.

There was an error sending your message. Please check to ensure ALL required fields are filled in and correct then try again. If this persists then please Contact the webmaster.

Required fields are missing. Please check that ALL fields marked with * are properly filled in.

Thank you for requesting a quotation from us. We endeavour to process quotation requests within 24 hours during normal working hours.

You Enquiry is currently being sent.

There was an error sending your message. Please check to ensure ALL required fields are filled in and correct then try again. If this persists then please Contact the webmaster.

There was an error logging in. Please check your username and password.

Success you are now logged in.

Please Wait

There was an error logging in. Please check your username and password.

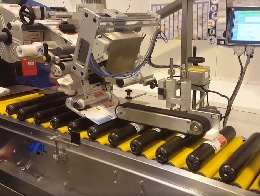

Our popular ALline horizontal roller conveyor labelling systems can take many forms and are used with a wide variety of product types - from pharmaceutical vials to salami sausage chubs!

They are particularly suited to products which either can not, or would not easily be labelled in a vertical format (on a standard ALline C labelling system or ALline 3-roller), and are designed and built specifically around the product samples presented accommodating any protrusions or caps etc where present.

Solutions can be offered on either our compact or standard ALline base platform, and feature as standard our ALline central management 'machine visualisation' control system, storing complete recipe formats, including mechanical positioning counter values for repeatable setup. We even include remote access support capabilities, as standard.

One of the benefits of a roller conveyor is the high-frequency and perfect pitching of product presentation, meaning even a basic specification machine is usually easily capable of more than 100 products per minute.

High-performance machines, perhaps supplemented by our servo-driven rotary carousel bulk hopper feeder (or vibratory bowl) can be capable of running at more than 200 pieces p/minute and can be supplemented by our full range of label checking, printing/coding and automatic rejection accessories where requested (see:ALpharma).

Most ALline Horizontal labelling systems operate in a continuous format, with the roller conveyor always moving at an even speed forwards.

However, in certain applications - usually, where there is a requirement to rotationally register the label, we can also offer an intermittent motion and matching pneumatic application system.

ALline Horizontal is a highly evolved and proven machine concept. Over the years we have refined the design (with features such as our central management control) to improve application precision and aid the user-friendliness of operation.

It is for this reason that we now fit as standard a 90-degree rotation bracket for the wraparound belt (where included) to allow its extraction and so easier threading of the labelling head at the peeler position.

For small diameter products, such as vials and tubes. we have recently developed a highly innovative roller adaption concept which uses a low-inertia cylinder to raise and lower on the product. This providing better drive (than a traditional belt) and ensures a more consistent rotation - which results in a more reliable higher precision application.

High-Speed Tube Labelling

High-Speed Tube Labelling

Perfume Tubes Horizontal Labelling

Perfume Tubes Horizontal Labelling

Horizontal Labelling with Auto Feeder

Horizontal Labelling with Auto Feeder

ALpharma ALline Horizontal with Hopper

ALpharma ALline Horizontal with Hopper

Test Tubes Indexing Conveyor

Test Tubes Indexing Conveyor

Sweets Tube Semi-Auto Feed & Labelling

Sweets Tube Semi-Auto Feed & Labelling

Haggis Chubbs with ICE Coder

Haggis Chubbs with ICE Coder

ALline Horizontal with Lip Balms

ALline Horizontal with Lip Balms

ALline Horizontal Pen Labelling

ALline Horizontal Pen Labelling

Syringe Labelling with Extended Infeed

Syringe Labelling with Extended Infeed

Contact ALTech UK to discuss your requirements with our experienced and knowledgeable team.

Contact UsContact ALTech UK to discuss your requirements with our experienced and knowledgeable team.

Contact UsContact ALTech UK to discuss your requirements with our experienced and knowledgeable team.

Contact Us