🌟☕ Introducing Our Advanced Pouch Labelling System for Coffee Roasters! ☕🌟 Revolutionise Your Coffee Packaging with Precision and Efficiency Welcome to the future of coffee packaging with our state-of-the-art pouch labelling system. Designed specifically for the dynamic needs of coffee roasters, our system offers a seamless, efficient solution for handling and labelling flexible coffee pouches. Whether you’re dealing with…

🏷️ Discover the Power of Precision with Our ALline Labelling System! 🍯 Did you know that honey, one of nature’s most enduring gifts, never spoils? Remarkably, edible honey was discovered in the ancient tomb of Tutankhamun, which is over 3,000 years old! While we can’t promise that our state-of-the-art ALline labelling system will last millennia, we’re confident in its…

We’re excited about this one! After many years of design and development, we are delighted to announce ‘ALrobot’, a fully robotic turn-key print and apply solution for pallet labelling. Part pallet, full pallet, double stack pallets, multiple label positions, extended strokes – all no issue with ALrobot pallet labeller. A step change in pallet labelling technology! If you are…

With ever-increasing autonomy in supply chain management and automated warehouses, the relevance of our proven and continually evolving Document Print and Insertion System🖨️📃– for pick notes, manifests, invoices, etc. —is becoming increasingly prominent, with solid demand for the product. In this recent installation, which was part of an enhancement/extension project of our customer’s mixed-case fulfilment warehouse, our leading system…

The craft brewing sector is a vibrant one, and we are pleased to be part of it!🍻 This recent ALline C wraparound labelling system cruises ✈️ at more than 180 cans per minute (or a theoretical 10,000 cans per hour, ignoring reel changes) for our well known Staffordshire based customer, and includes intelligent load control to ensure smooth operation…

Fully refurbished ALstep S labelling head (S, 100mm version) with fixed speed wide belt (400mm) conveyor (we have the possibility to configure the required running speed up to 27m/min). 1500mm in length. Single phase power supply. Adjustable anti-friction side guides. Photocell product detection. Left to right operation. Immediate availability. 6 months parts and labour warranty where sold with onsite…

Looking for an offline solution to label pouches or bags?🛍️ We are confident that we can provide a solution like this innovative ‘angled stack’ reverse shingle pick-and-place feed system, which operates in this video with a premium coffee pouch that includes a zip-lock. The feed concept shown is a development of our UK team and one of many solutions…

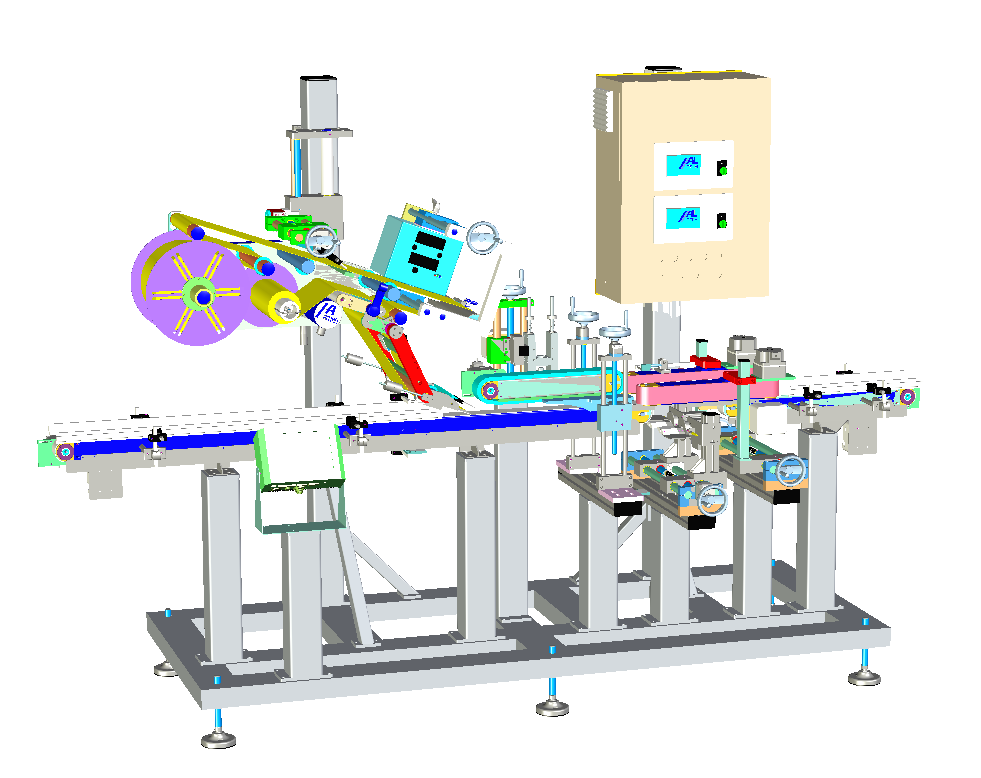

This is a fantastic opportunity to purchase a unique ALbelt D-wrap labelling machine for trays and skin packs. The machine can fully wrap a label around a product to provide a result a little like a sleeve (or you can also use the machine for top labelling or watchstrap labelling – potentially even C-wrap labelling where labels are orientated…

Do you need to integrate a labelling head into your bagging or flow-wrapper machine, either as a manufacturer or end-user customer looking for a retrofit solution, perhaps to apply a promotional or ‘peel-reseal’ label? In simple terms, there usually are two main complexities to this application: mounting the machine/adapting the machine to fit within a specific space, and synchronisation…

ALline E, with power movement for automatic setup, is the pinnacle of front and back labelling technology! Our UK demo machine is available for product trials and review. This is a rotated machine, meaning we will almost always have a machine of this configuration available and in stock, available for short lead time supply where suitable and depending on…