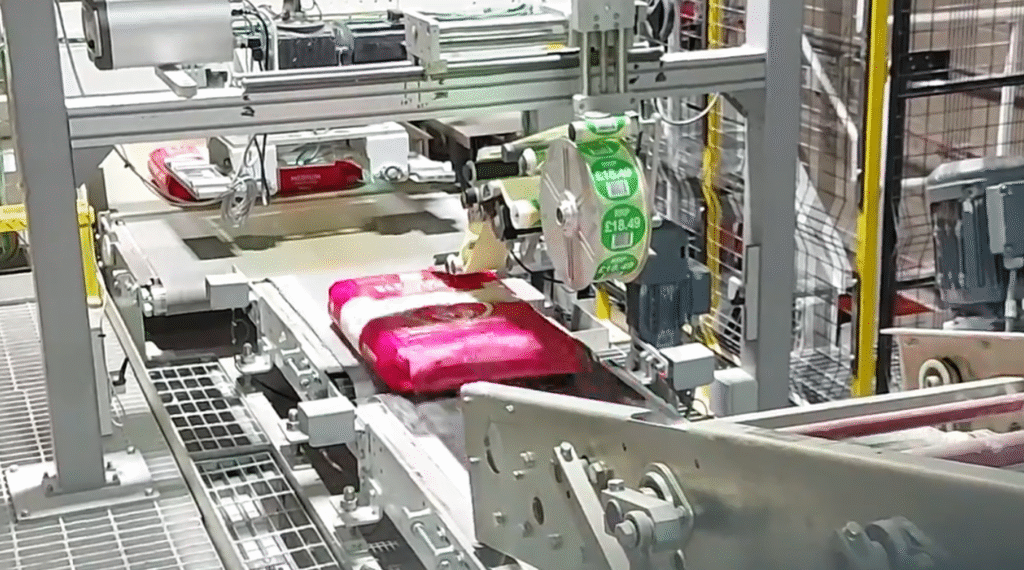

Automation only makes sense if you can trust it to work autonomously 🤖 Watch this ALritma labelling head working synchronously as part of an automatic sack palletisation system for one of the UK’s leading mills. The system runs continuously – reliably – and entirely hands-free. In fact, the machine is so critical to the process that the customer keeps…