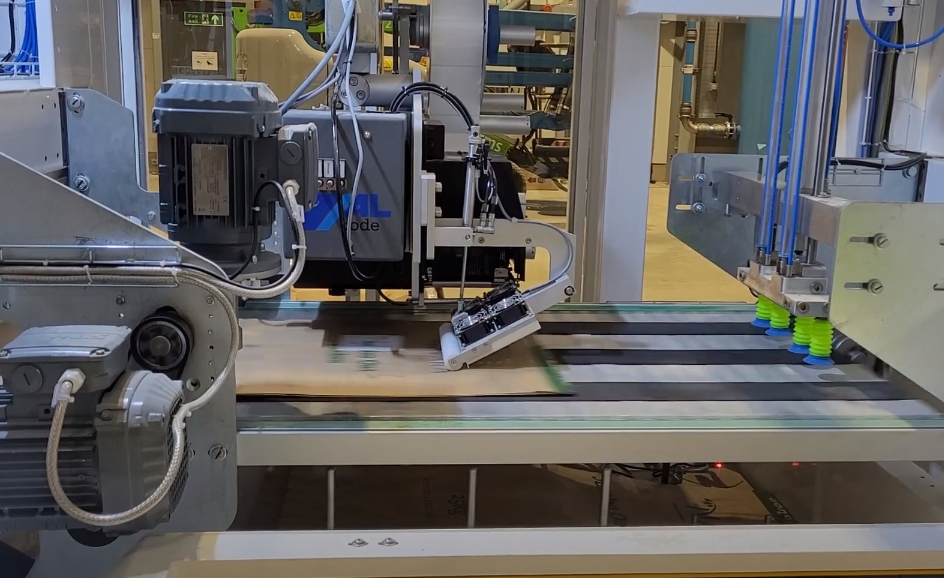

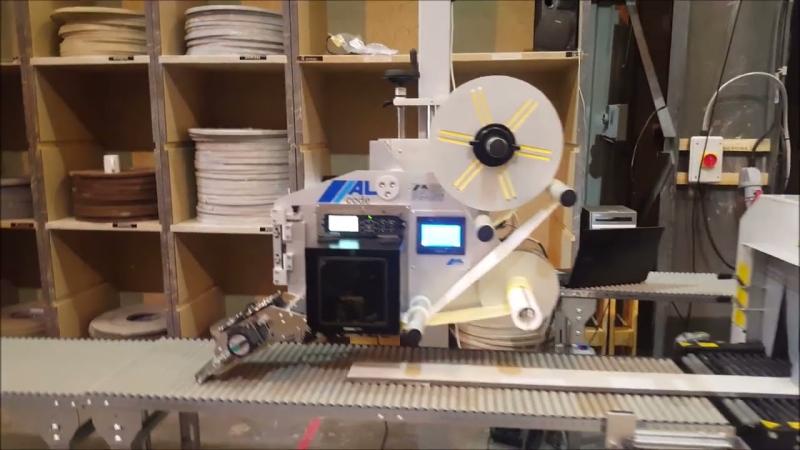

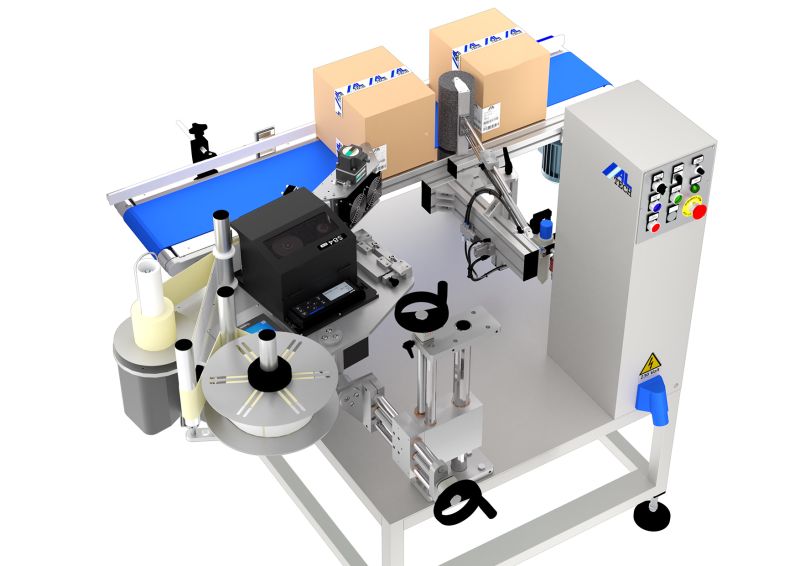

Tamp/Tamp-Blow/Air-Blow application methods 🌬️ are commonly used with print and apply machines because they allow the label to be printed in a different rotation to its application, e.g. printed Portrait, applied Landscape. These solutions all have their place, but often, they are selected through necessity – being the only option available to the competitor – and are not ideally…