Installations in Focus – Flexible Paint Tin Labelling System 🎨🎥

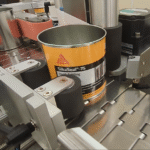

Here we have one of the most flexible paint tin labelling systems you’re likely to see – built for a UK supplier of metal cans for paints, varnishes, fillers and similar products, who offers pre-labelling as a service.

Their production demands flexibility:

• Can sizes from 125ml to 5L

• Seam alignment across the full range

• On larger tins, lug and seam registration where the label cut-out must align accurately

But the key point is this:

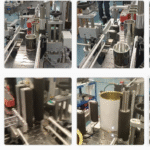

There is nothing unusual about how this machine has been designed.

While it is tailored to the product range, the flexibility comes directly from our standard ALTech design philosophy for cylindrical labelling – not from one-off engineering or special adaptation.

This is why it is simple and repeatable to set up:

🔹 Central management control – product programs selected at the touch of a button

🔹 Prescriptive mechanical adjustments using a clear setup schedule

🔹 Change-part roller array, with rollers sized and pitched correctly for the can family

And, as always, the machine is built to a high mechanical standard, ensuring stability, ease of use, and long-term reliability.

This is what we mean when we say ALTech offers Best Value.

All customers benefit from this — but for some, it is even more obvious.

#ALTech #LabellingSolutions #MetalPackaging #PaintTinLabelling #EngineeringExcellence #BestValue