ALcode with ‘air-blast’ applicator is an ideal print and apply solution for bakery products, as demonstrated in this recent video. Like all ALcode machines, the solution offers the ability to change the label data at the touch of a button (e.g. for short batch runs), combined with a non-contact application compatible with the delicate nature of the product, including…

Feeding crash lock boxes is not easy because the shape of the box is not regular, meaning it is difficult to manage any significant stack of boxes, required to make an automatic feeder useful. This print and apply labelling solution presents one of a number of feed concepts we have to solve this challenge, also featuring our ALcode one-to-one…

A shortage of sunflower oil and the profound effect this could have on the food industry is currently dominating the news; see BBC NEWS for further details. In 2020 we supplied this non-stop ALline labelling system to ADM in Erith (featured in the above article) to label large bottles of sunflower oil, which present the difficult combination to handle…

Something a little different from a normal labelling requirement – brand labelling large metal oil drums avoiding the need to have pre-printed drums tieing up stock. This novel solution was conceived and built by our UK team with the concept adaptable to many applications. #drums #barrels #labelling #ALTech #labelingmachine #oil

This recently supplied twin-head print and apply labelling system is one of two units placed with a leading UK manufacturer of insulation products, able to label a wide variety of both rectangular and cylindrical ‘batt packs’ and ‘roll packs’, applying A5 product labels at high-speed and without stopping using manageable size label reels (in terms of weight/operator loading) due…

This advanced three conveyor section twin-head non-stop base labelling system for sliced meat trays (also with the possibility of top and bottom labelling) provides significant operation efficiencies by limiting changeover downtime. See further examples of our wide-ranging (built to spec) top and bottom labelling solutions HERE. #Labelling #meatindustry #meatprocessing #fishingindustry #packagingmachinery #packagingequipment #packaginginnovations #packagingindustry #supplychain #packaging #machinery #manufacturing

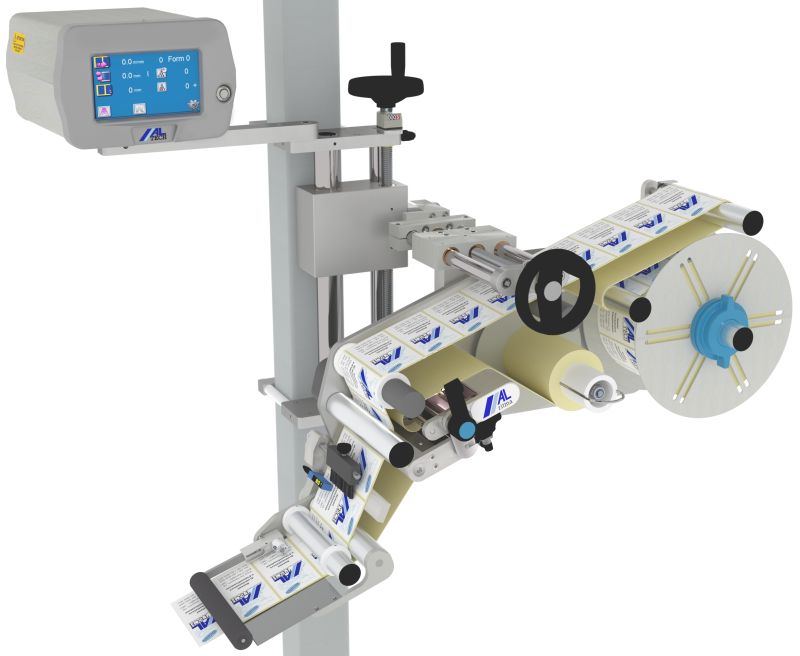

ALcode is a genuine ‘one-to-one’ print and apply machine, where the last label printed is the label then applied (without any label buffer), ensuring data integrity. It is available with one of the widest ranges of proven module application solutions of any machine on the market for label application on almost any face, fully optimised to the application’s requirements….

We are excited to share with you the next generation of Zebra Technologies industrial print engines – the ZE511 (4″) and ZE521 (6″) machines, just released to the market, and forming the backbone of many future ALTech print and apply solutions. Watch this video for an overview of the many new features of the machines. For the logistics market,…

Our already renowned high performance ALritma label applicator has just got better! For 2022, we can now offer the machine with what we believe to be the largest full-colour touch screen of any stand-alone label applicator on the market. This new 7″ display provides increased user-friendliness and memory capabilities, Industry 4.0 connectivity, and an innovative SOS support function. #ALTech…

Does your outer case box or shrink tray labeller ever miss? If so, it is likely that the products arrived too close together, meaning the tamp/tamp-blow application system could not recover in time. With our fully electric ALcode ‘Vacuum Belt’ print and apply machine, this is rarely a problem, shown here in our archive video cruising at 76 labels/min…