We recently supplied this high-speed print and apply labelling system for retail magazines, working in line with an automatic feeder and restacking system to apply barcode ID/price point labels for foreign markets. The ALTech solution included (in-house developed) bespoke control software that imported the customer’s data file to send the correct print information, and a barcode scanner to reconcile…

Artisan food producers often prefer to use a more traditional ‘hotfoil’ (or embossed) label coding solution for Batch & Expiry information for both practical and aesthetic reasons. #artisanfood #sauces #labelling #coding #ALTech

‘Direct wraparound labelling’ is both a fast and flexible cylindrical product labelling solution, allowing application on-the-fly and commonly used with all types of round products from jars, to bottles, to vials. We offer a number of build levels of machine, from basic entry-level ALbelt systems to our robust and performing ALline C series machines, which are optimised for inline…

Our dual-lane 3-roller ALline labelling system combines high-speed with high-accuracy round product labelling and is particularly suited to toiletry and cosmetic applications. It also allows the possibility of rotating registering the label, e.g., to the seam of an aerosol can, providing a highly effective linear labelling solution where normally a larger (and significantly more expensive) rotary solution would be…

ALcode is a silent workhorse, labelling mail order cartons with both licence plate (LPN) and shipping labels quickly and efficiently in many leading UK automated logistics warehouses. In this video, we are using a SATO Europe S84EX print engine, applying unique LPN barcode labels to adjacent side faces of a ‘just erected’ carton, which will then be allocated and…

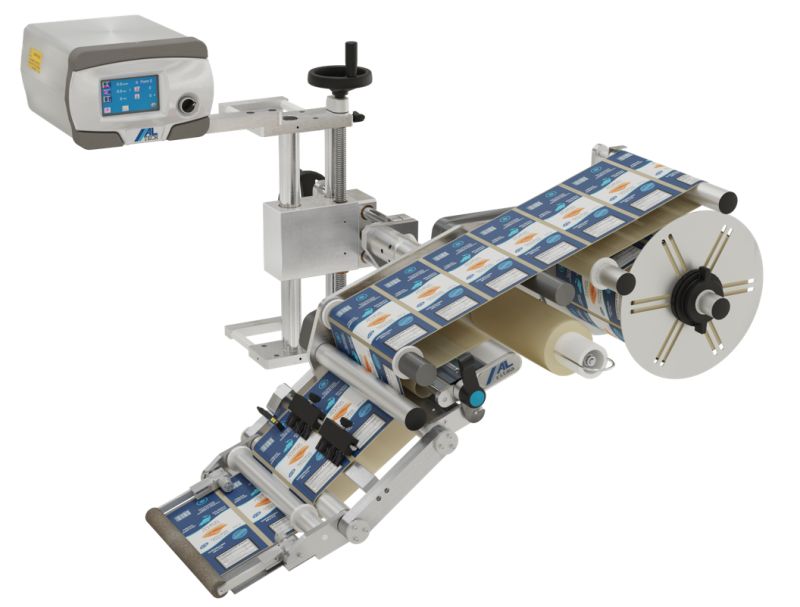

ALritma is a performance labelling head available in three size versions; 100mm (S), 200mm (M) and this, the biggest and most robust model, 300mm (L). Such a wide label feed width allows the application of labels as large as ‘A3’ or even bigger! Here is an example from our archive applying an A3 size label to a flat bag…

We recently supplied this simple ‘pack turning’ supplementary infeed conveyor to our food supplements customer to allow direct feeding of their ALbelt labelling machine. Each reverse tuck carton is then labelled on horizontally opposed ends to seal the carton securely, completing the application in a fully automatic format. See the system in operation HERE. #labelling #labeling #labelingsolutions #labelingmachine #cartons…

We often speak about the flexibility our labelling machines can offer: this ALline 3-Roller machine is a great example, able to label food supplement containers that vary dramatically in size from large to small either empty or full. This is facilitated via the machines modular design and central management recipe controller meaning the setup is simple and repeatable. #Labelling…

Thanks to everyone who visited our stand today at the #PPMAshow. With two more days to go we look forward to more surprised faces when realising we really can switch between products at the touch of a button! #ppma #labelling #packaginginnovations

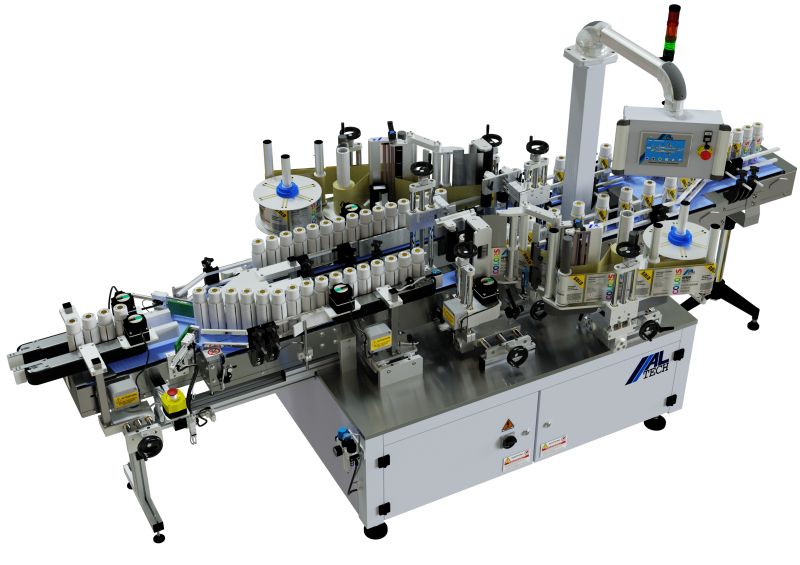

Combining our ALfeeder friction feeder and ALritma labelling head, this recent turnkey feed and labelling system for flat cartons allows our snack foods customer to quickly & efficiently over-label printed flat cartons, covering the existing nutritional and barcode information with foreign market-specific labels to allow them to sell their product in foreign markets with different legislative requirements. See HERE…