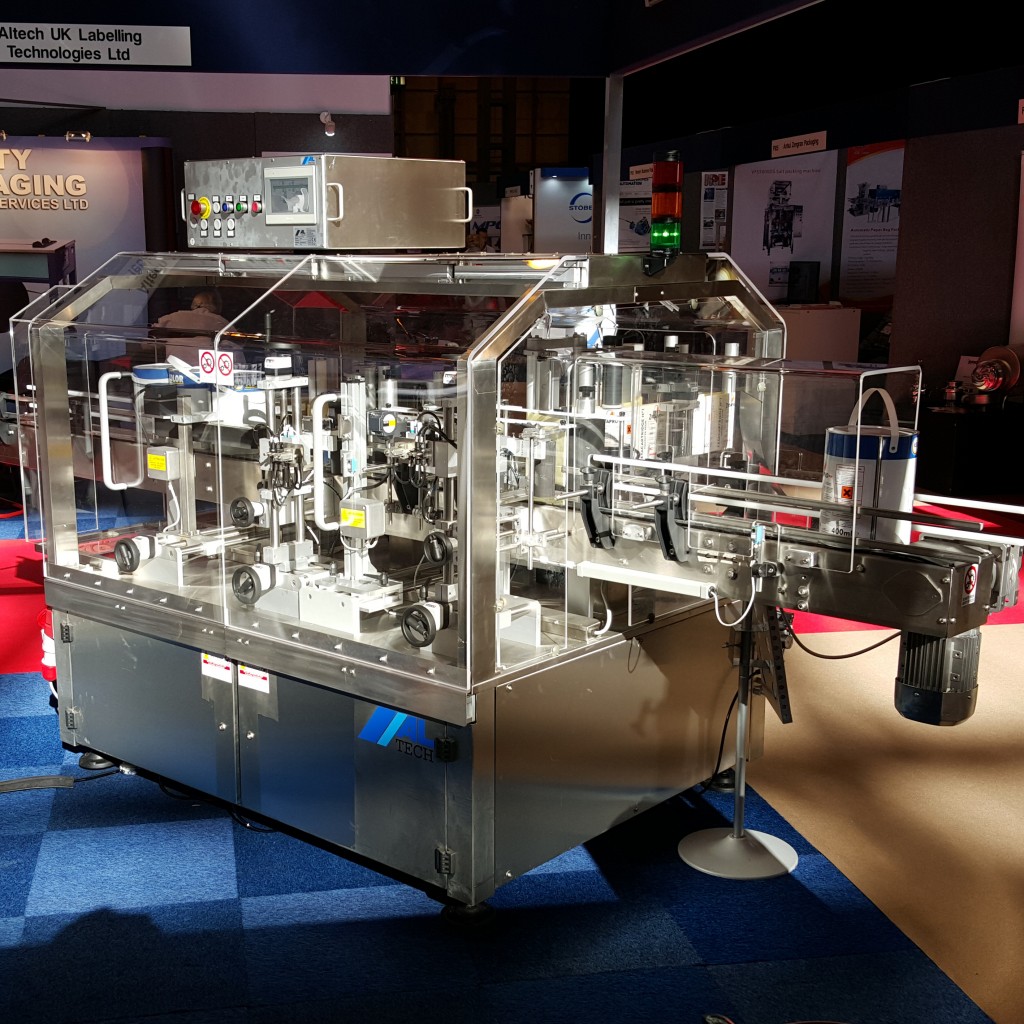

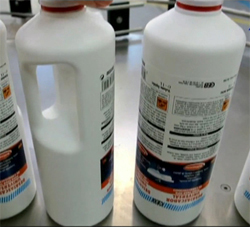

ALTech have recently constructed a jar labelling system for Kesbeke, a Dutch producer of pickled vegetables. Kesbeke required a machine to apply a variety of labels onto glass jars, each of which has a specific function: decorative, tamper evident, promotional and/or informative. The solution was designed to insert into their existing production line, and is capable of labelling 90 products per…