ALTech would like to thank everyone who visited them at the PPMA show this year. It was a busy three days and we had plenty of footfall on the stand; both from our existing loyal customers who we are always happy to see and some exciting new leads which we will be following up over the coming days. As is always the case at these events, there were a couple of people that we did not get chance to speak to fully and we would like to apologise for this. Be assured though, if we have your contact details we will be in touch shortly.

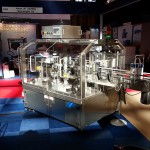

The star of the show this year was our fully automated ALline paint can labelling system, making a complex task of registering two labels to the seam of the can, as well as lifting the handle and printing and applying a swatch label, an effortless and precise operation. The machine caught many an eye and did a fantastic job of pulling in the crowds.

Another winner on the stand was the outstanding quality of the branded sweets – produced by our customer Liquid Lens on their two ALTech machines supplied early this year. The sweets proved extremely popular and needless to say we didn’t take any home with us at the end of the show. We had three products on offer – tubes of smarties and skittles, pots of jelly beans and pouches of smarties.

The tubes were labelled on an ALline Horizontal labelling machine with an integrated innovative hopper infeed unit and the pouches and pots were labelled on a single multi functional ALbelt machine. The versatility of the ALbelt solution allows both pouches to be automatically fed onto a conveyor (by our new ALfeed friction feeder) and labelled by an ALritma applicator with ICE printer, and pots to be inducted from a rotary table and labelled with a tamper seal. The tamper label is initially applied ‘flagged’ on the product and then adapted in ‘watchstrap’ format via simple pneumatic system. The machine is designed to run at a conservative 50-60 p/min to match the rate of other operations such as filling, capping etc. Videos of both machines can be viewed below.

Liquid Lens are a longstanding customer of ours and also have a low cost ALwrap machine for small volume orders.