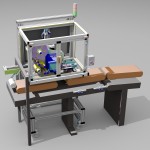

ALTech have designed and built a filled sack labelling machine for Fosroc, a world leading manufacturer of specialist chemicals to the construction industry. The UK plant in which the machine was installed was an exceptionally dusty environment, and as such, full enclosure of the machine was necessary, including an underside pneumatic door opening system during the label application.

The purpose designed machine is a variant of our ALcode one-to-one print and apply applicator series, and uses an innovative swinging plate application pad which follows the uneven shape of the bag as well as self adjusting to variable heights. This well proven system is used by Fosroc to label the bags lay flat on the conveyor, however the solution can also be tailored to standing sacks fed from the side of line.

Fosroc have used our machine to switch from pre-printed bags to labelled sacks, reducing their unit cost and providing them with greater flexibility and the ability to use a standardised bag and monitor stock/batch control. They also utilise ALTech’s ALsoft design software to dynamically produce complex labels with images and variable text including tabled information on demand and pre-programmed to align with specific print runs.

A particular challenge of Fosroc’s requirements was speed. Whilst the actual bag throughput and thus label rate was not particularly high (approximately 15 bags p/min maximum), the short distance between the outfeed of the bag filling system and robot palletiser meant that the flow of bags to the labelling machine was not evenly regulated.

To overcome this, the machine was programmed with special logic to monitor the distance between bags using the secondary ‘door open’ sensor. In the event that the preceding bag was too close to allow a full ‘down’ application stroke of the machine its cycle pattern is dynamically varied, immediately returning the application pad to the printer and using a spring loaded adaption roller to complete the application on the outfeed.

During the final testing stage it became evident that the machine was able to complete a full cycle, by using the high speed capabilities of a SATO print engine, even when the bags are fed close together. This solution demonstrates ALTech’s ability to tailor the integration of their machines to specific customer requirements, with the flexibility to adapt their systems during the evolution of the build.